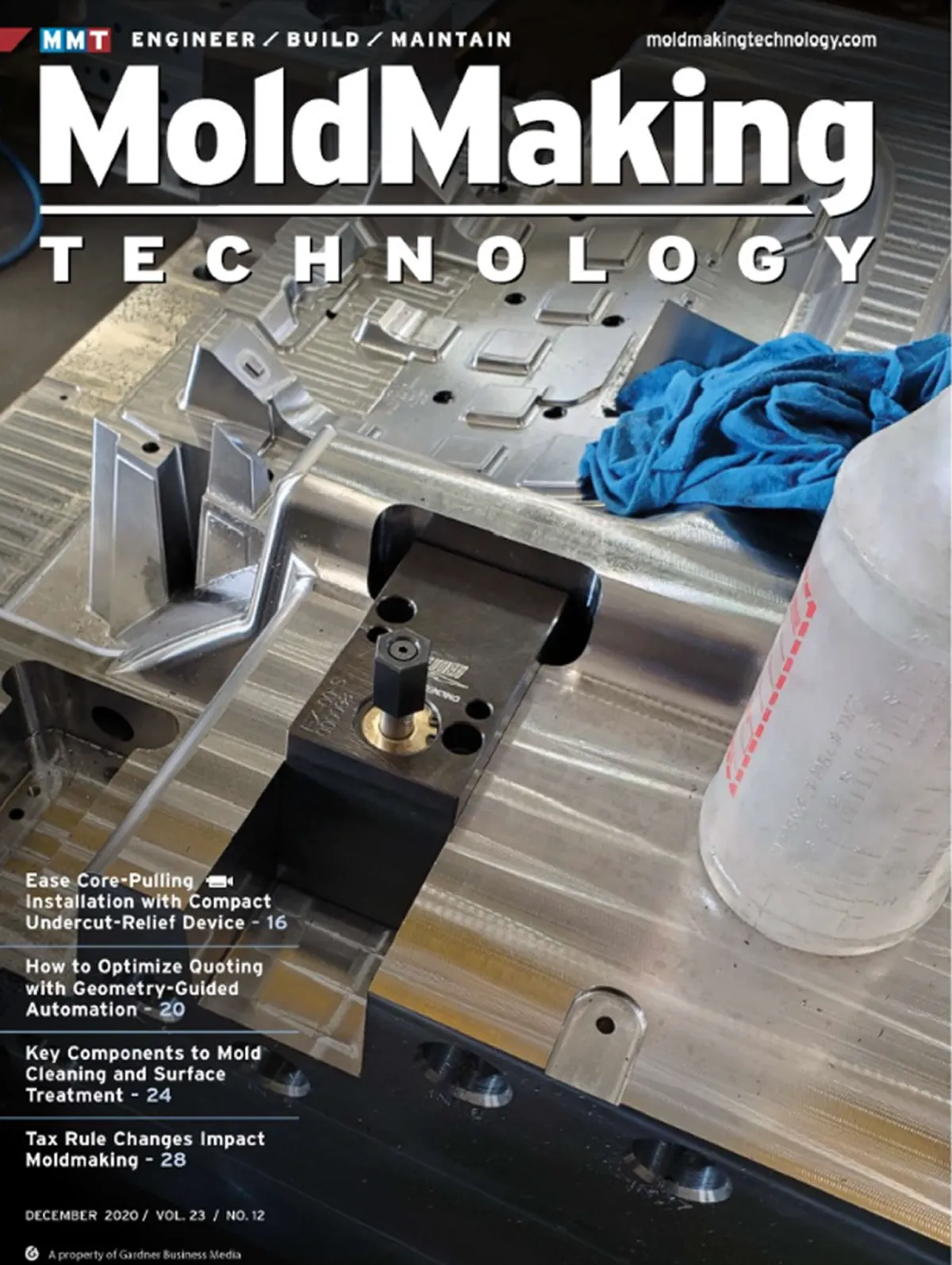

A Single-Unit Undercut Relief System

A compact solution for molding undercuts and part features. This self-contained unit simplifies the process by using plate action to activate a hydraulic plunger, creating the desired part feature. With EZ SLIDER, there's no need for complex machining setups or multiple components. Just machine a pocket, drop in EZ SLIDER, and you're good to go. Our angled units offer flexibility, with standard increments up to 35° or custom angles available. Say goodbye to expensive hydraulic cylinders and additional components — EZ SLIDER streamlines your molding process.

“When we used the EZ Slider on that first tool, we found it to be very straightforward, very simple to install and use and it took up a lot less room in the tool."

John Murphy, President

Venture Global Engineering (VGE) of Sterling Heights, Michigan.

A Single-Unit Undercut Relief System

A compact solution for molding undercuts and part features. This self-contained unit simplifies the process by using plate action to activate a hydraulic plunger, creating the desired part feature. With EZ SLIDER, there's no need for complex machining setups or multiple components. Just machine a pocket, drop in EZ SLIDER, and you're good to go. Our angled units offer flexibility, with standard increments up to 35° or custom angles available. Say goodbye to expensive hydraulic cylinders and additional components — EZ SLIDER streamlines your molding process.

Why EZ Slider?

Single unit undercut relief system

Eliminates the need for expensive slides, slide components and complex hydraulic setups

Cycle tested to 1,000,000 without failure

Convenient for designers and mold makers.

Design is simple with supplied cad data.

Install from the parting line with ease.

Cuts overall costs of multiple aspects of the mold design, build & maintenance.

Compact size

Adjustable stroke of up to .390"

No blowback due to being backed up by cavity steel & hydraulic fluid.

Capable of pulling features up to 35° deceleration.

Custom angles available upon reset.

“I’d say it easily saves 50% of the time it normally takes to install a slide and… it doesn’t leak and flash the way a conventional slide can."

John Murphy, President

Venture Global Engineering (VGE) of Sterling Heights, Michigan.

Why EZ Slider?

Single unit undercut relief system

Eliminates the need for expensive slides, slide components and complex hydraulic setups

Cycle tested to 1,000,000 without failure

Convenient for designers and mold makers.

Design is simple with supplied cad data.

Install from the parting line with ease.

Cuts overall costs of multiple aspects of the mold design, build & maintenance.

Compact size

Adjustable stroke of up to .390"

No blowback due to being backed up by cavity steel & hydraulic fluid.

Capable of pulling features up to 35° deceleration.

Custom angles available upon reset.

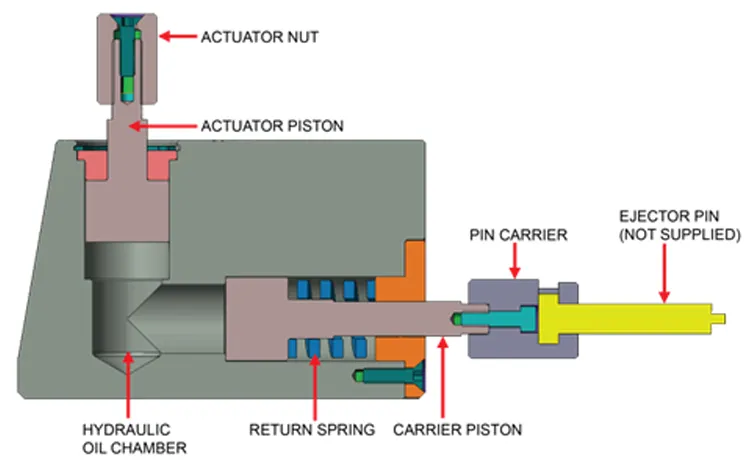

How Does it Work?

The cutaway view reveals the internal mechanism of the EZ SLIDER. When compressed, the actuator is released, and the return spring retracts the spring rod, preparing the molded part for ejection.

EZ SLIDER angled units are available and come in standard 5° increments of deceleration up to 35°. Undercuts can be relieved where traditional slides or lifters cannot be utilized giving molders more design and manufacturing flexibility. Eliminating the need for costly mechanical or hydraulic cylinders, external limit switches, mounting plates. Eliminates the manufacture time and materials for additional components

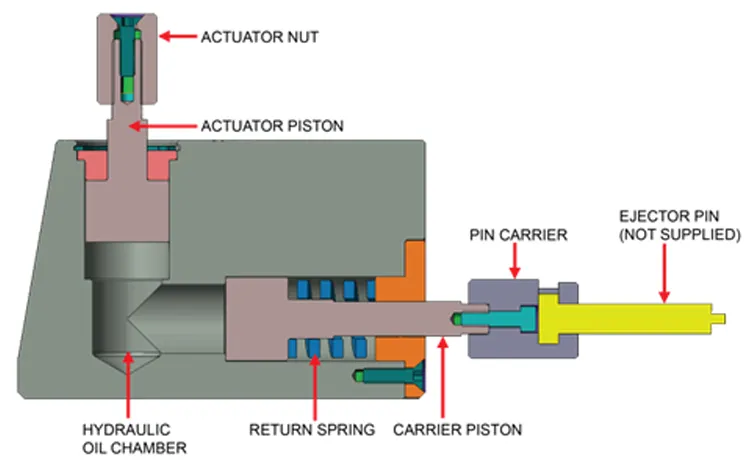

How Does it Work?

The cutaway view reveals the internal mechanism of the EZ SLIDER. When compressed, the actuator is released, and the return spring retracts the spring rod, preparing the molded part for ejection.

EZ SLIDER angled units are available and come in standard 5° increments of deceleration up to 35°. Undercuts can be relieved where traditional slides or lifters cannot be utilized giving molders more design and manufacturing flexibility. Eliminating the need for costly mechanical or hydraulic cylinders, external limit switches, mounting plates. Eliminates the manufacture time and materials for additional components

Frequently Asked Questions

What is EZ Slider?

EZ Slider is an innovative undercut relief system designed to simplify the molding process. It utilizes plate action through a hydraulic plunger to create the desired part feature, eliminating the need for complicated machining or additional components.

How does the EZ Slider enhance the molding process?

EZ Slider offers several benefits including:

-Reduction in the need for expensive slides and complex setups.

-A simple design that can be easily incorporated using supplied CAD data.

-Cost savings on mold design, construction, and upkeep.

-Compact with an adjustable stroke up to .390 inches.

-No blowback, as it's supported by cavity steel and hydraulic fluid.

-Customizable angles for versatile application needs.

What makes EZ Slider different from traditional slides?

The EZ Slider stands out because it:

-Is a self-contained unit, streamlining the molding process.

-Requires less space and is quicker to set up than traditional slides.

-Has been cycle-tested to 1 million uses without failure.

-Can be installed directly from the parting line.

-Reduces the necessity for costly external components and additional manufacturing.

Can EZ Slider handle different part features and angles?

Absolutely. EZ Slider is capable of pulling features with up to 35° deceleration, with angled units available in standard 5° increments. This flexibility allows for relieving undercuts where traditional slides or lifters might not be suitable.

Is the EZ Slider a safe component to include in my molding process?

Yes, the EZ Slider is designed for safety and reliability. It operates without leakage or flashing and is securely backed by cavity steel and hydraulic fluid to prevent blowback.